Aluminium is a versatile and widely used material in various industries, including construction, automotive, and aerospace.

In the context of glazing applications, the choice of aluminium grade plays a crucial role in determining the overall performance, durability, and aesthetic appeal of windows and doors. This article delves into the different grades of aluminium, their properties, and how these characteristics influence their suitability for glazing applications.

The Basics of Aluminium Grading

Aluminium grades are categorised based on their alloy composition, which significantly impacts their properties such as strength, corrosion resistance, and malleability. These grades are designated by a four-digit number, where the first digit indicates the primary alloying element. The most common aluminium grades used in glazing applications fall within the 1000, 3000, 5000, 6000, and 7000 series.

1000 Series: Pure Aluminium

The 1000 series aluminium, often referred to as pure aluminium, contains a minimum of 99% aluminium. This series is known for its excellent corrosion resistance and high thermal and electrical conductivity. However, pure aluminium is relatively soft and lacks the strength required for structural applications.

In glazing, 1000 series aluminium is typically used in non-structural components where maximum corrosion resistance is desired, such as in decorative trims and window screens. Its high malleability allows for easy forming and shaping, making it suitable for intricate designs. However, due to its lower strength, it is less commonly used in load-bearing or high-stress applications.

3000 Series: Manganese Alloy

The 3000 series aluminium is alloyed with manganese, which enhances its strength compared to the 1000 series while maintaining good corrosion resistance. This series is also known for its excellent workability and moderate strength, making it a popular choice for general-purpose applications.

In the context of glazing, 3000 series aluminium can be found in window frames and components that require moderate strength and corrosion resistance. Its ability to resist weathering makes it suitable for outdoor applications, although it is generally not used in high-load-bearing structures.

5000 Series: Magnesium Alloy

The 5000 series aluminium is alloyed with magnesium, providing a significant boost in strength and corrosion resistance. This series is particularly well-suited for marine environments due to its ability to withstand harsh conditions. The addition of magnesium also improves its welding characteristics, making it easier to join components.

For glazing applications, 5000 series aluminium is often used in structural components where higher strength and durability are required. It is commonly utilised in the construction of large sliding doors and windows, where the frames must support considerable weight while resisting environmental stressors such as wind and saltwater exposure. The superior corrosion resistance of this grade ensures longevity and reduced maintenance in coastal or industrial environments.

6000 Series: Silicon and Magnesium Alloy

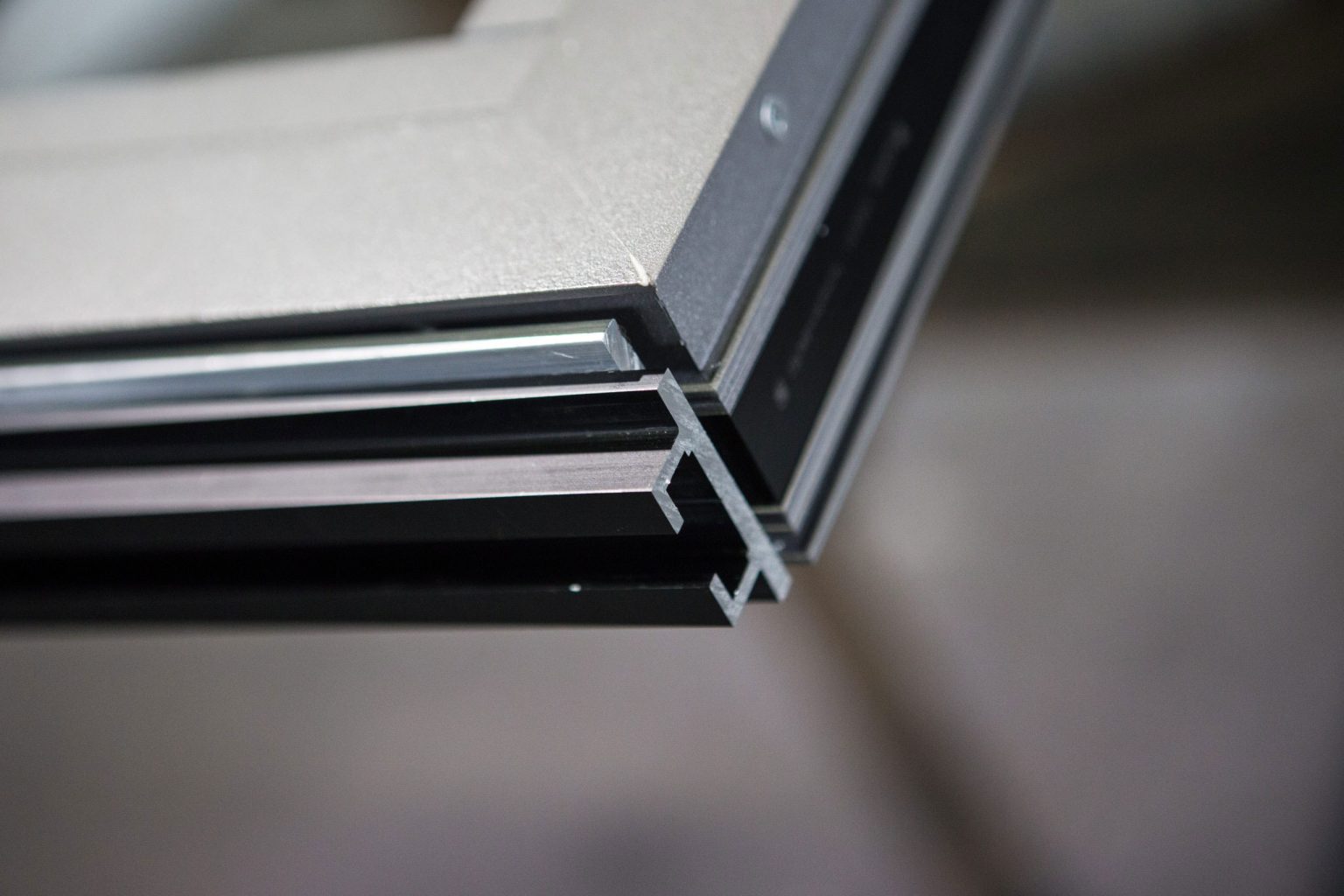

The 6000 series aluminium is one of the most widely used in construction and glazing applications due to its balanced properties. This series is alloyed with both silicon and magnesium, resulting in excellent strength, corrosion resistance, and machinability. The 6000 series is also highly versatile, with good weldability and the ability to be heat-treated for enhanced performance.

In glazing, the 6000 series is the go-to choice for window and door frames, curtain walls, and other structural components. The combination of strength and workability allows for the creation of slim yet robust profiles that maximise the glass area while maintaining structural integrity. This series is particularly favoured in modern architectural designs that demand both aesthetic appeal and high performance.

7000 Series: Zinc Alloy

The 7000 series aluminium is alloyed with zinc, making it the strongest of all the aluminium grades. This series is primarily used in aerospace and high-stress applications where maximum strength is required. However, the higher zinc content also makes it more susceptible to stress corrosion cracking, which can be a concern in certain environments.

In glazing applications, the 7000 series is less commonly used due to its high cost and specific properties that may not be necessary for typical building environments. However, in projects where exceptional strength is required—such as in large, load-bearing structures or specialised architectural designs—the 7000 series may be utilised. Its use in such scenarios ensures that the glazing system can withstand extreme forces while maintaining its structural integrity.

How Aluminium Grades Influence Glazing Applications

The choice of aluminium grade in glazing applications directly impacts several key factors, including:

- Structural Integrity: Higher-grade aluminium, such as the 6000 and 7000 series, provides the necessary strength for load-bearing applications, ensuring that windows and doors can support the weight of large glass panes and withstand environmental forces.

- Corrosion Resistance: Aluminium grades with higher corrosion resistance, such as the 5000 series, are ideal for coastal or industrial environments where exposure to saltwater or pollutants is a concern.

- Aesthetic Appeal: The malleability and workability of aluminium, particularly in the 1000 and 3000 series, allow for the creation of custom shapes and designs, contributing to the overall aesthetic of the building.

- Durability and Maintenance: Aluminium grades that offer a balance of strength and corrosion resistance, such as the 6000 series, ensure that glazing systems remain durable and require minimal maintenance over time.

- Cost Efficiency: The choice of aluminium grade also affects the overall cost of the glazing system. Higher-grade aluminium, while offering superior properties, may come at a higher price point, so selecting the appropriate grade based on the specific needs of the project is crucial.

Understanding the different grades of aluminium and their properties is essential for making informed decisions in glazing applications. The choice of grade affects not only the performance and durability of the glazing system but also its aesthetic appeal and cost-efficiency. By selecting the appropriate aluminium grade for each specific application, architects and builders can ensure that their glazing solutions meet the highest standards of quality, performance, and longevity.